Carbon Steel Tube Mill

We adhere to customer satisfaction as the primary goal of our business, and this is not just a commitment but a core value ingrained in our company culture. We recognize that each customer's needs are unique and significant, which is why our carbon steel pipe manufacturing equipment goes beyond standard solutions—it is a tailored, customized solution perfectly aligned with the characteristics of your business.

Uncoiler & Accumulator

The key equipment used for uncoiling metal coils. It efficiently and stably unrolls coiled metal strips or wires into flat bands, providing an ideal foundation for subsequent processing. Equipped with a tension control system, it ensures material stability during the uncoiling process. Easy to operate, it offers both manual and automatic modes to meet different production needs. The high-efficiency feeding and stacking machine provides reliable material supply for the production line, ensuring a smooth production process.

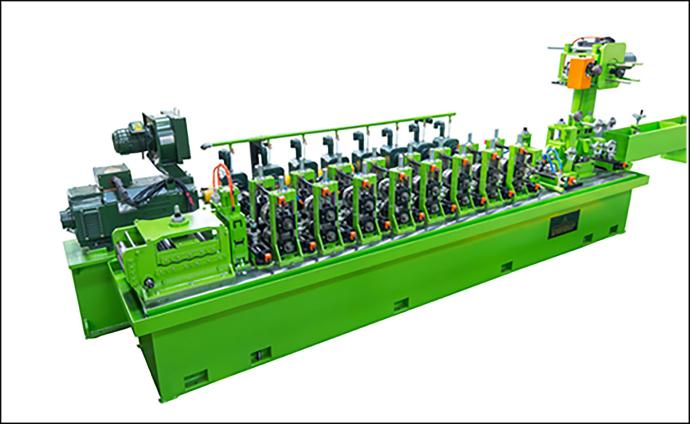

Forming Mill

Utilized for shaping metal strips or steel coils to produce various types of pipes, the efficient Pipe Forming Machine boasts a precise control system. Capable of transforming flat metal materials through pressure and shape molds into round, square, or other specialized pipe shapes, this machine excels in highly automated, fast, and stable production. Widely applied in construction, automotive, energy, and other industries, it offers diverse pipe solutions suitable for varying tube sizes and thickness requirements.

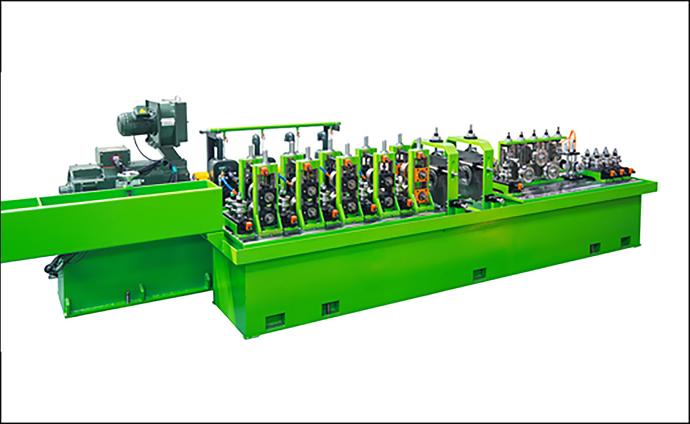

Sizing Machine

A crucial equipment in the steel tube production process, the Diameter Forming Machine stands out with its exceptional features. Not only does the machine achieve high-precision straightening, ensuring that the steel strip reaches the desired diameter and roundness, but it also incorporates multi-roller forming technology to effectively shape the steel strip, guaranteeing product quality. Its rapid adjustment capability allows it to accommodate the production of tubes with different specifications, enhancing production flexibility. Equipped with an automatic control system, it enables real-time monitoring and adjustment, boosting production efficiency and ensuring consistent product quality.

High-Frequency Welder

This machine employs high-frequency electromagnetic fields to generate intense heat, swiftly melting both ends of the steel strip and welding them together, achieving the production of seamless steel tubes. Its features include high efficiency, rapid welding speed, and excellent welding quality. The high-frequency welding machine can adapt to various steel types and different thicknesses of steel strips, equipped with an automatic frequency adjustment function to ensure a stable welding process. With an advanced control system, it achieves precise control of welding parameters, enhancing production efficiency. Widely utilized in construction, manufacturing, and other fields, it caters to diverse requirements for seamless steel tubes.

Servo Cold Cutting System

Designed for precision cutting of metal tubes to ensure products meet the required dimensions and specifications, this efficient machine features advanced cutting technology. Capable of swiftly and accurately fulfilling various cutting needs, including straight, beveled, and custom-angle cuts, the cutting machine is equipped with an automated control system, ensuring both production efficiency and cutting quality.

Run-out Table

The main function of the run-out table is to receive, discharge, and organize the cut steel tubes after the tube manufacturing process. Its design prioritizes production efficiency and operational convenience, ensuring the smooth flow of steel tubes on the production line. The run-out table rapidly receives the cut steel tubes, preventing product accumulation, and organizes them systematically for subsequent packaging or transportation. Additionally, the equipment ensures the horizontal movement of steel tubes, preventing damage or deformation. Its stable operation and efficient discharge function contribute to enhancing the overall efficiency of the production line, making the steel tube manufacturing process more seamless.

Rollers

These rollers are used to support, guide, and transmit steel strips or tubes, ensuring they maintain the correct orientation and stable operation throughout the entire manufacturing process. The design of the rollers takes into account the characteristics of the materials to reduce friction and support weight. Rollers in different positions may have various shapes and functions, such as shaping rollers, transmission rollers, and support rollers. These rollers collaborate throughout the production line, ensuring that steel strips or tubes acquire the proper shape and dimensions during the manufacturing process.

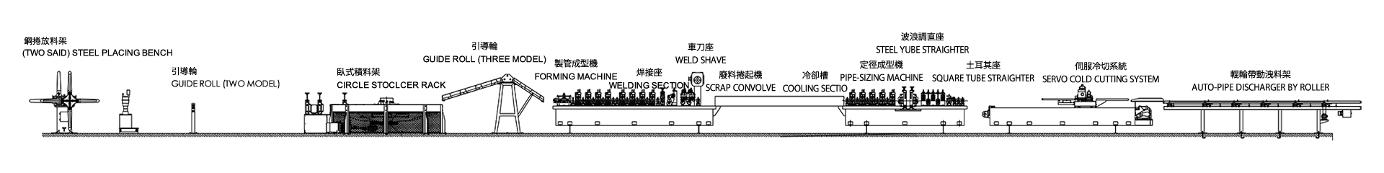

Carbon Steel Tube Mill Configuration Diagram (Pipe making machine production line Configuration Diagram)

Specifications

| Model |

External Diammeter |

Plate Thickness |

Speed

|

High-frequency

|

Accumulator Power

|

Foming Power

|

Cutter Power

|

| 135 |

φ9.6mm~φ31.8mm |

0.3mm~1.6mm |

30~100m/Min | 100kw | DC 15kw | DC 47kw | AC 30kw |

| 160 |

φ12mm~φ42mm |

0.4mm~1.8mm |

30~100m/Min |

150kw |

DC 15kw |

DC 60kw |

AC 35kw |

| 180 |

φ16mm~φ42mm |

0.5mm~2.5mm |

30~100m/Min |

150~200kw |

DC 15kw |

DC 77kw |

AC 35kw |

| 220 | φ19mm~φ63mm |

0.7mm~3.2mm |

20~90m/Min |

200~250kw |

DC 30kw |

DC 115kw |

AC 39kw |

| 260 |

φ25mm~φ76(95)mm |

1.0mm~3.6mm |

20~90m/Min |

300kw |

DC 36kw |

DC 153kw |

AC 45kw |

| 300 | φ42mm~φ114mm |

1.2mm~4.5mm |

15~70m/Min |

400kw |

DC 44kw |

DC 188kw |

AC 54kw |

| 350 | φ60mm~φ166mm |

1.6mm~6.0mm |

15~60m/Min |

500kw |

DC 75kw |

DC 300kw |

AC 61kw |